SAGA TEKKOHSHO COMPANY

It was founded in Mexico in May 2012.

SAGA TEKKOHSHO Mexicana is the fourth company established abroad within the global SAGA TEKKOHSHO group.

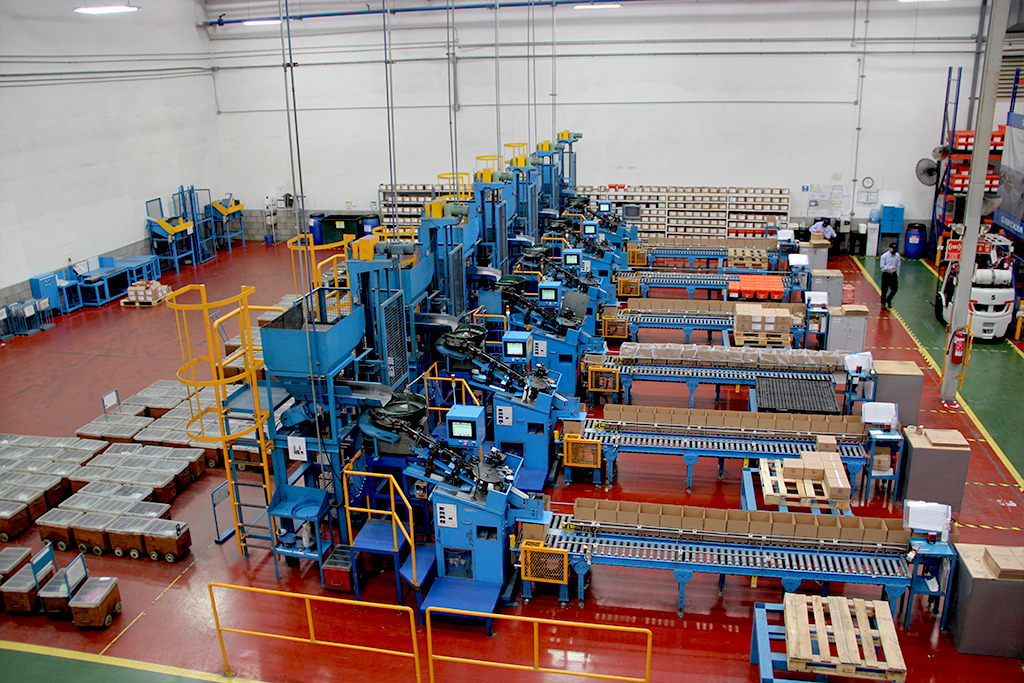

It was founded in Mexico in May 2012 and in December 2013 started the production of Fasteners. In order to transmit our knowledge and manufacturing technology of our products we have as a foundation the training of all our staff in our facilities.

In addition, we continue to grow by obtaining certification in IATF 16949:2016 and those that are considered requirements of our customers as CQI-9 (Heat Treatment) and CQI-11 (Galvanized).

Saga Tekkohsho Mexicana is part of the Saga Tekkohsho Group, which has 4 plants in Japan and presence in the United States, China, Thailand and Mexico.

- SAGA PLANT, SAGA PREFECTURE, JAPAN.

- FUJISAWA PLANT, KANAGAWA PREFECTURE, JAPAN.

- OMACHI PLANT, SAGA PREFECTURE, JAPAN.

- TAKU PLANT, SAGA PREFECTURE, JAPAN.

- DEXTER FASTENER TECHNOLOGIES, INC.

- SHANGHAI TEQIANG FASTENER TECHNOLOGY CO,.LTD.

- SAGA FASTENER (THAILAND) CO., LTD.

- SAGA MEXICANA PLANT, GUANAJUATO MEXICO.

– President.

Environmental Policy Quality Policy. Timeline

OUR PRODUCTS

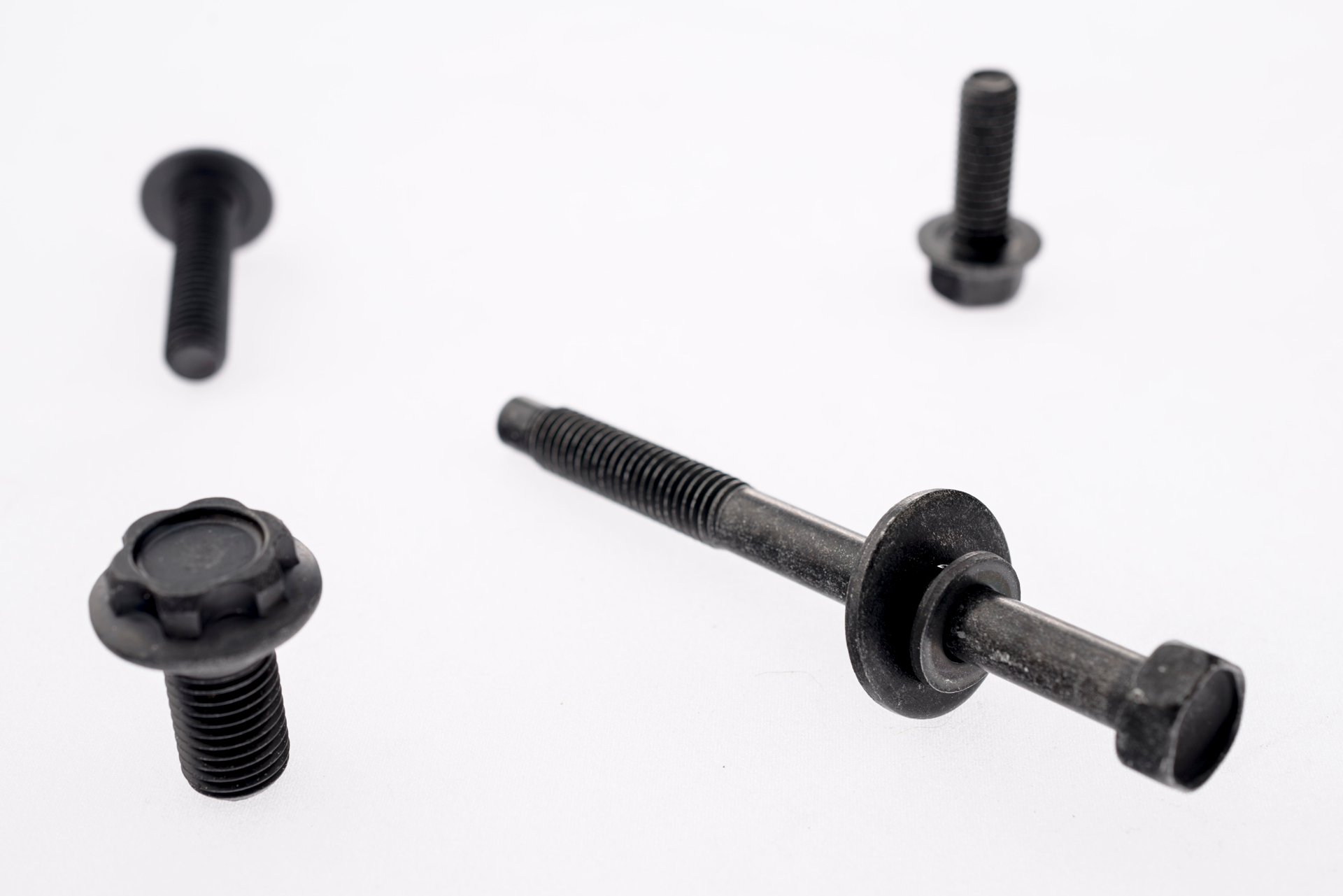

OUR PRODUCTS, QUALITY, PERFORMANCE AND PRECISION

IMPORTANT PART

“Screws are parts with a great mission, since they have the strength to join two parts making people’s lives easier”.

INTERNATIONAL PRESENCE

Saga Tekkohsho Group has 4 plants in Japan and presence in the United States, China, Thailand and Mexico.

CONSTANT TRAINING

We have as a foundation the training of all our staff in our facilities.

CERTIFICATIONS

We have International Certifications, IATF 16949:2009, CQI-9 (Heat Treatment), CQI-11 (Galvanizing), ISO 14001:2015 and Q1 Ford.

SAGA TEKKOHSHO COMPANY

Products

Saga Mexicana’s products are focused on the automotive industry and we take the mission of offering high quality, performance and precision screws very seriously.

We have built a production system that meets the needs of our customers while maintaining the same quality standards of Japan.

The screw may not appear to be a very important part, but its function is immeasurable.

Our products guarantee safety and peace of mind to end users, since approximately 700 bolts of 150 different types are used in a vehicle.

Saga Mexicana’s product range covers application ranges for engine, brakes, suspension, chassis, seat and transmission among others.

Bolts are parts with a great mission, since they have the strength to join two parts making people’s lives easier.

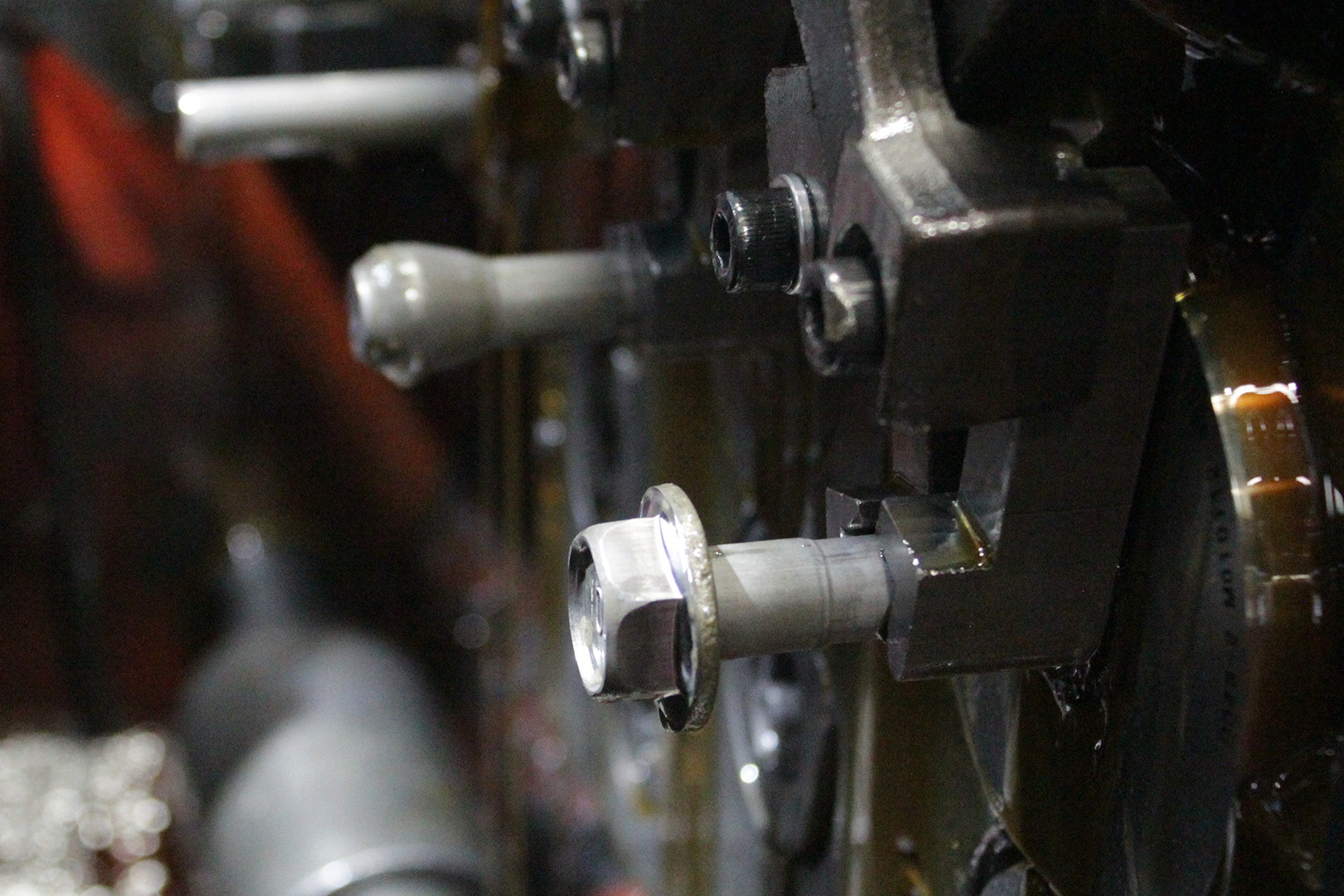

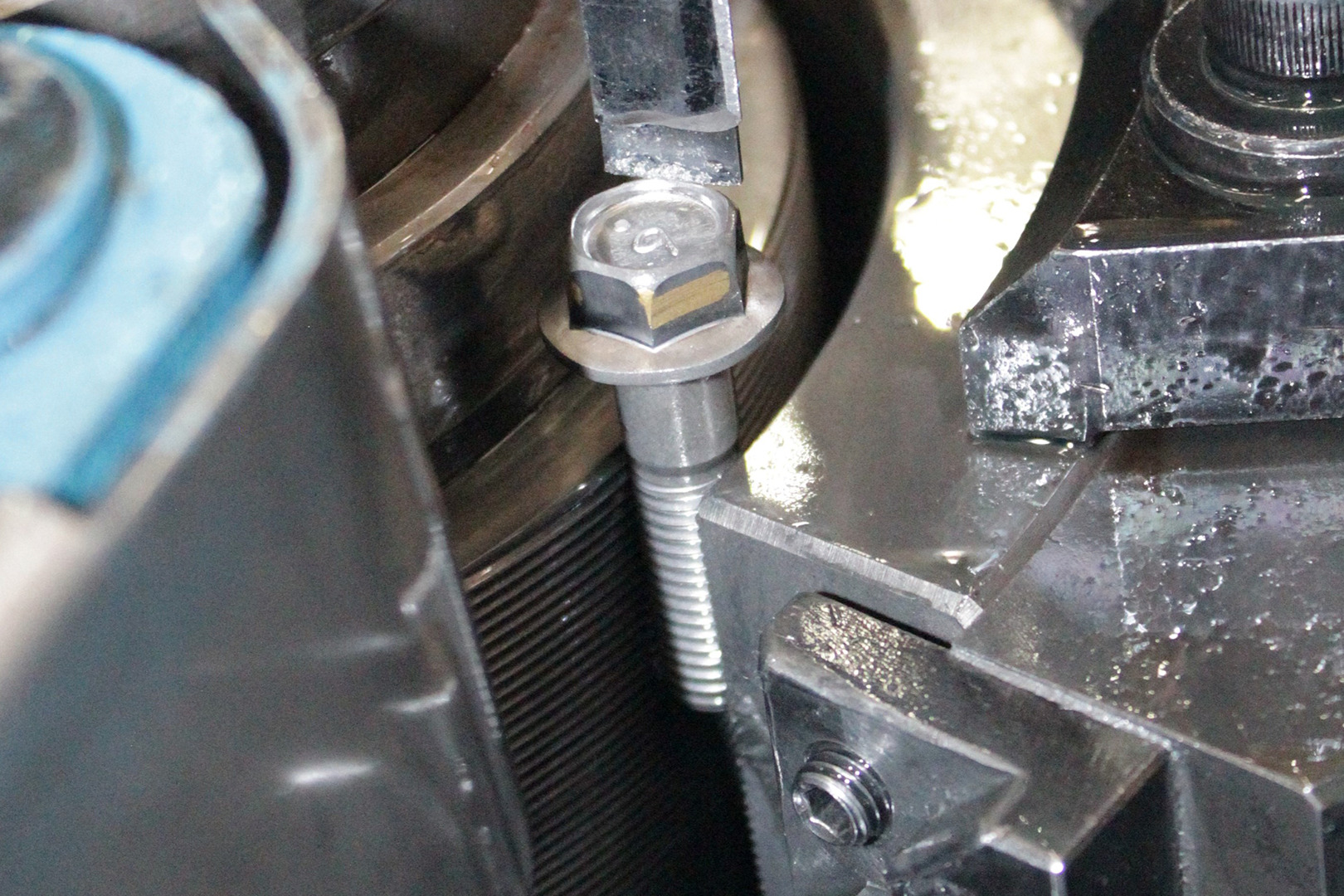

In Saga Mexicana we have in-house processes based on innovation and development of new technologies, which allow us to have a wide flexibility and control of them, fully complying with the needs and requirements of our customers.

OUR PROCES

Cold Forging

Process in which the body, head of the materials are shaped.

Rope forming

Process by which the rope is generated in the materials.

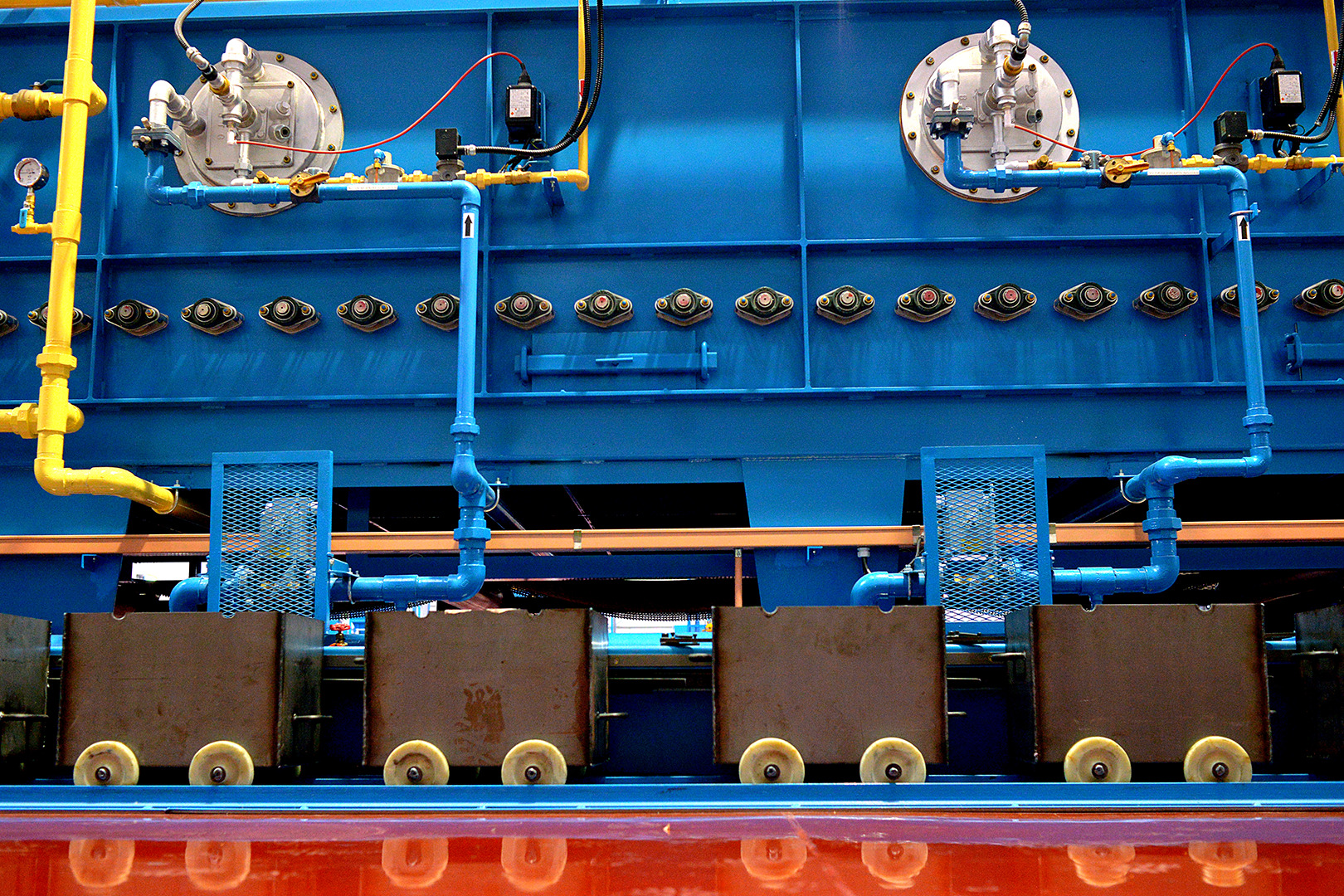

Heat treatment

Process to give resistance and stabilize characteristics and properties of materials.

Surface treatment

Process to improve the corrosion resistance and appearance of the material.

Mechanical inspection

Inspection process to the finished product where 100% of the parts are verified.

SAGA TEKKOHSHO COMPANY

We have high technology and precision equipment that allows us to carry out an exact measurement and control of our products.

Site area: 88,627 m2 (21.9 acres)

Built-up area: [Office] 1,120 m2(12,060ft2) [Plant] 8,392m2 (90,330ft2).

Inspection equipment:

- Tensile testing.

- Profile measurement.

- Rockwell hardness Microvickers hardness.

- Salt chamber test.

- X-ray thickness gauge.

- Torque tension test.

Main machinery:

- Stamping: Stamping machine: (Cold forging) 16 units (M6-M14).

- Rolling: (Flat, segmented dies) 12 units.

- SEMS: (Laminated with washer) 4 units, laminated (Cylindrical) 1 unit.

- NC: (Pointing) 1 unit.

- Heat Treatment Furnace: 2 units.

- Zinc Galvanizing, Baking and Waste Water Treatment: 1 line. (Finigard, Torquer and TNT15).

We have a strong commitment to the environment, through environmentally friendly processes and continuously working to minimize the environmental impact with our facilities dedicated to wastewater processing and air emissions control.

SAGA TEKKOHSHO COMPANY

Global Network

Saga Tekkohsho Mexicana is part of the Saga Tekkohsho Group, which has 4 plants in Japan and presence in the United States, China, Thailand and Mexico.

Previo

Siguiente

OUR CUSTOMERS

QUALITY THAT PROVIDES QUIETNESS

In addition to offering peace of mind and satisfaction to our customers, we add value by providing high quality products, thus becoming an essential part of the automotive industry.

MISSION SAGA TEKKOHSHO

Mexicana S.A. de C.V. is an international company dedicated to the manufacture of fasteners, with people committed to providing high quality products and services that exceed customer expectations.

Contact US

Adress

Río Ota #631, Parque Tecnoindustrial Castro del Río.

Irapuato, Guanajuato, México.

ventas@satetsu.com.mx

Phone

(462) 166-3400

Business hours

Lunes – Viernes

08:00 a.m a 05:30 p.m